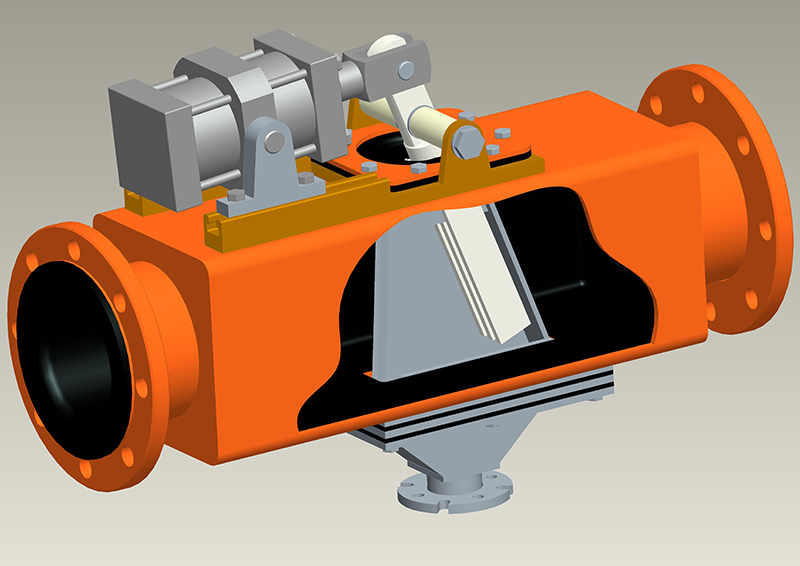

Laboratory Rotary Sampler Iron Slurry Analyzer

Product Description

Laboratory Rotary Sampler Iron Slurry Analyzer

The demands on modern day mineral processing plants are enormous, which means Mining Slurry Sampler control and monitoring is of paramount importance. Slurry Sampler Design is a valuable tool to assist with optimisation and maximising of recoveries and grade. The accuracy of the sample is directly related to the design of the sampler. Since sampling is based on statistics, the minimising of statistical errors maximises the accuracy.

Slurry Sampler Equipment can be supplied for a variety of applications in the mineral processing industry. Some applications where Iron Slurry Detector sampling has proved invaluable include:

• Cyclone Overflow (flotation feed)

• Final Tailings

• Intermediate Base Metal Concentrates

• Final Flotation Concentrate

• Carbon-in-Leach Streams

Slurry Samplers are designed to operate continously for 24 hours per day. Process selections are based on our Inspection System and vast experience in the field of slurry sampling. It is our belief that process equipment should not be designed on the limit since mettallurgical operations are dynamic.

Technical Parameters

1) Dimension & Weight of the instrument

Net weight (Exclusive of IPC and sampler): 900kg

External dimension (L*W*H): 2200*1500*1700mm

Basic maintenance area: 3000*2500mm

2) Technical parameters

Detected parameter: iron grade

Measuring time: 1 second

Detected process technology types: raw ore, concentrate and tailing

Detected precision: typical precision 0.5 (1δ), depends on the site condition.

3) Installation requirements

Installation space: not less than 2500*1500*2000mm

Flow rate requirement: 8-10 m³/h

Grounding requirement: resistance to ground < 4Ω

Power supply requirement: 220VAC±10%,50Hz±5%,2KW

Wash water requirement: clean water with no suspended particle, 0.3MPa < Pressure < 0.5MPa

Gas requirement: clean and continuous gas, 0.4MPa < Pressure < 0.8MPa

Applications of the product in mineral processing automatic control systems

· Real-time: Displays grade value every second so that the operator can know the production condition in time, enables rapid adjustment and avoid bad influence on product quality due to lagged chemical analysis

· Adaptability: Adopts single point measurement, main measuring unit can be installed in a whole or in disassembled parts according to the site condition. It has strong site adaptability.

· Low maintenance workload: Remote or local flush on pipeline can be achieved by installing automatic flushing device, thus to significantly reduce the workload of instrument maintenance.

· Radiation safety: Adopts scintillation detector with high sensitivity and efficiency, significantly reduces the dose of radioactive source and guarantees the radiation safety performance.

Radiation dosage around the instrument is less than 2.5μSv/h.

· Durability: Non-contact measuring method is adopted to ensure the long and stable operation of the instrument.

· Friendly operating interface, easy for operation.

Product Categories : Iron Slurry Analyzer